Introduction

In industrial environments, safety and reliability are paramount, particularly when dealing with hazardous locations where flammable gases, vapors, or liquids are present. The National Electrical Code (NEC) and the Canadian Electrical Code (CEC) classify these hazardous locations to ensure that electrical equipment is designed and installed to minimize explosion risks. One critical classification is Class I, Division 2 (CID2), which pertains to areas where hazardous substances are not normally present in ignitable concentrations but may exist under abnormal conditions.

For industrial electrical control systems, understanding Class I, Division 2 is essential for selecting and installing appropriate enclosures, components, and wiring methods to ensure both safety and regulatory compliance. This paper explores the significance of CID2 classification, recommended enclosures, and best practices for implementing electrical controls in these environments.

Understanding Class I, Division 2

The NEC and CEC define hazardous locations based on the presence and likelihood of flammable gases, vapors, or liquids. Class I locations involve environments where these substances exist, and Division 2 specifically refers to areas where they are only present under abnormal conditions, such as equipment malfunctions or system failures.

Common Examples of CID2 Locations:

- Oil refineries and petrochemical plants

- Waste treatment facilities

- Chemical manufacturing plants

- Fuel storage and dispensing areas

- Pharmaceutical production environments

- Food processing plants using flammable solvents

While the presence of hazardous materials in these areas is not constant, the potential for accidental leaks, spills, or failures makes explosion-proof or intrinsically safe equipment a necessity. Industrial electrical control systems operating in these zones must meet stringent safety and durability standards to prevent ignition sources from triggering catastrophic events.

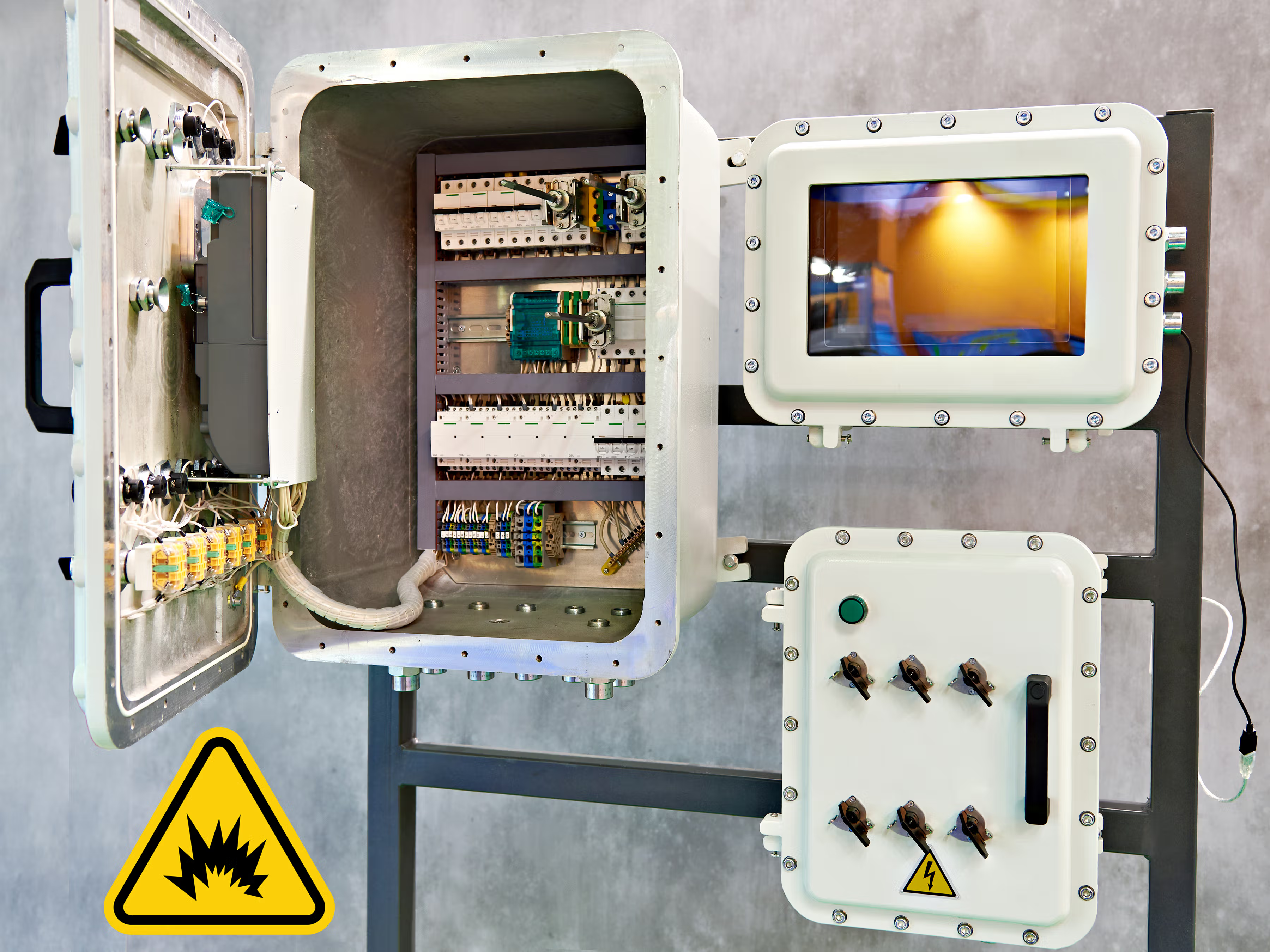

Recommended Enclosures for Class I, Division 2

Electrical enclosures play a critical role in protecting control systems from external environmental hazards while containing any potential sources of ignition. The type of enclosure used must comply with CID2 requirements, which focus on preventing arc, spark, or heat emissions from igniting a hazardous atmosphere.

Explosion-Proof vs. Non-Incendive Enclosures

For Class I, Division 2 applications, two primary types of enclosures are used:

- Explosion-Proof Enclosures (Type 7)

- Designed to contain any internal explosions without allowing external hazardous atmospheres to ignite.

- Typically made from cast aluminum or stainless steel.

- Rated for Class I, Division 1 & 2 environments, but often over-engineered for CID2 applications.

- Non-Incendive or Purged/Pressurized Enclosures

- Used to prevent hazardous gases from entering and accumulating inside the enclosure.

- Require proper ventilation and purging mechanisms to maintain safe internal pressure.

- Common in control panels, PLC cabinets, and HMI enclosures.

NEMA Ratings for CID2 Enclosures

The National Electrical Manufacturers Association (NEMA) sets enclosure standards for hazardous locations. The most commonly used NEMA enclosure ratings for CID2 include:

- NEMA 4X: Provides weatherproof, corrosion-resistant protection, ideal for outdoor applications.

- NEMA 7: Explosion-proof enclosures designed for indoor Class I hazardous locations.

- NEMA 9: Dust ignition-proof enclosures used in Class II locations but sometimes applicable to mixed hazardous environments.

- NEMA 12: Offers dust and drip resistance, commonly used in CID2 industrial control cabinets.

Best Practices for Installing Industrial Electrical Controls in CID2 Areas

Proper selection, installation, and maintenance of industrial electrical controls in Class I, Division 2 locations ensure both compliance and operational safety. Key best practices include:

Selecting Certified Electrical Equipment

Industrial electrical components used in CID2 areas must be certified to meet hazardous location standards. These include:

- UL (Underwriters Laboratories) Listing for Class I, Division 2

- FM (Factory Mutual) Approval

- CSA (Canadian Standards Association) Certification

Using CID2-rated push buttons, relays, sensors, and motor controls ensures that no components generate excess heat, sparks, or arcs that could ignite flammable atmospheres.

Wiring Methods and Conduit Sealing

Electrical conduit and cabling used in hazardous locations must meet CID2 specifications:

- Use seal-off fittings within 18 inches of the enclosure to prevent gas migration through conduit runs.

- Implement Type MC-HL (Metal Clad Hazardous Location) armored cables for robust protection.

- Adhere to intrinsically safe wiring techniques for sensitive control circuits.

Implementing Intrinsic Safety Barriers

For control circuits operating at low power levels, intrinsically safe barriers ensure that even in failure conditions, the circuit does not release enough energy to ignite a hazardous atmosphere. These systems limit current and voltage levels, making them a reliable solution for CID2 sensor and monitoring systems.

Using Purge and Pressurization Systems

When electrical control panels must be located within a CID2 area, a purge and pressurization system (Type X, Y, or Z) ensures that hazardous gases cannot accumulate inside the enclosure. These systems:

- Continuously flush the enclosure with clean air or inert gas to maintain internal pressure.

- Prevent gas ingress, reducing the risk of ignition.

- Allow the use of general-purpose electrical equipment inside the pressurized enclosure.

Conducting Regular Inspections and Maintenance

Routine inspections ensure that enclosures, wiring, and electrical components remain compliant and operational. Recommended practices include:

- Periodic testing of conduit seals and checking for deterioration.

- Inspecting enclosure gaskets for signs of wear or corrosion.

- Verifying the integrity of grounding systems to prevent electrostatic discharge.

Conclusion

Industrial electrical controls operating in Class I, Division 2 locations require specialized enclosures, certified components, and proper installation techniques to ensure safety, compliance, and reliability. CID2-rated NEMA enclosures, explosion-proof equipment, non-incendive designs, and intrinsic safety measures play a crucial role in preventing ignition sources from triggering fires or explosions in hazardous atmospheres.

By following best practices, including correct wiring methods, pressurization, and routine maintenance, industries can confidently deploy electrical control systems in CID2 environments while minimizing risks. As technology evolves, ongoing adherence to NEC, CEC, and UL/FM standards ensures that electrical controls in hazardous locations remain safe, efficient, and compliant with regulatory requirements.

References

- National Fire Protection Association (NFPA). (2023). NFPA 70: National Electrical Code (NEC). Quincy, MA: NFPA. Retrieved from www.nfpa.org

- Occupational Safety and Health Administration (OSHA). (2002). Hazardous Locations and Explosion Protection. OSHA Publication 3073. Washington, DC: U.S. Department of Labor. Retrieved from www.osha.gov

- Underwriters Laboratories (UL). (2019). UL 698: Standard for Industrial Control Equipment for Use in Hazardous Locations. Northbrook, IL: UL Solutions. Retrieved from www.ul.com

- Factory Mutual (FM) Global. (2018). FM 3615: Explosion-Proof Electrical Equipment Approval Standard. Norwood, MA: FM Approvals. Retrieved from www.fmglobal.com

- Canadian Standards Association (CSA). (2020). CSA C22.1: Canadian Electrical Code, Part I. Toronto, ON: CSA Group. Retrieved from www.csagroup.org

- National Electrical Manufacturers Association (NEMA). (2022). NEMA 250: Enclosures for Electrical Equipment (1000 Volts Maximum). Rosslyn, VA: NEMA. Retrieved from www.nema.org

- International Society of Automation (ISA). (2021). ISA-RP12.06.01: Recommended Practice for the Classification of Hazardous Locations. Research Triangle Park, NC: ISA. Retrieved from www.isa.org

- Methods Machine Tools, Inc. (2024). Industrial CNC Machining Solutions. Retrieved from www.methodsmachine.com

- Rockwell Automation, Inc. (2023). Industrial Control Panels for Hazardous Locations. Milwaukee, WI: Rockwell Automation. Retrieved from www.rockwellautomation.com

These references provide authoritative sources on hazardous locations, explosion protection standards, and industrial electrical controls. They ensure that the information presented aligns with regulatory requirements and best practices for Class I, Division 2 environments.

----------------------------------------

Descargo de responsabilidad:

El contenido proporcionado en este documento técnico está destinado únicamente a fines de brindar información general y se proporciona en el entendimiento de que los autores y editores no se dedican a la prestación de servicios de ingeniería, consultoría u otros servicios profesionales. La práctica de la ingeniería está impulsada por circunstancias específicas y únicas para cada proyecto. En consecuencia, cualquier uso de esta información debe realizarse solo con previa consulta a un profesional calificado y con licencia que pueda tener en cuenta todos los factores relevantes y los resultados deseados. La información de este documento técnico se publicó con un cuidado y una atención razonables. Sin embargo, es posible que parte de la información contenida en estos documentos técnicos esté incompleta, sea incorrecta o no se aplique a circunstancias o condiciones particulares. No aceptamos responsabilidad por pérdidas directas o indirectas que resulten de usar, confiar o actuar sobre la información en este documento técnico.

ISO 9001:2015

Certificado

Más de 17 millones de productos

Configuraciones

Toda la vida

Garantía

Garantizado

Envíos en el mismo día

Precios ventajosos

Ahorre hasta un 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009