Introduction

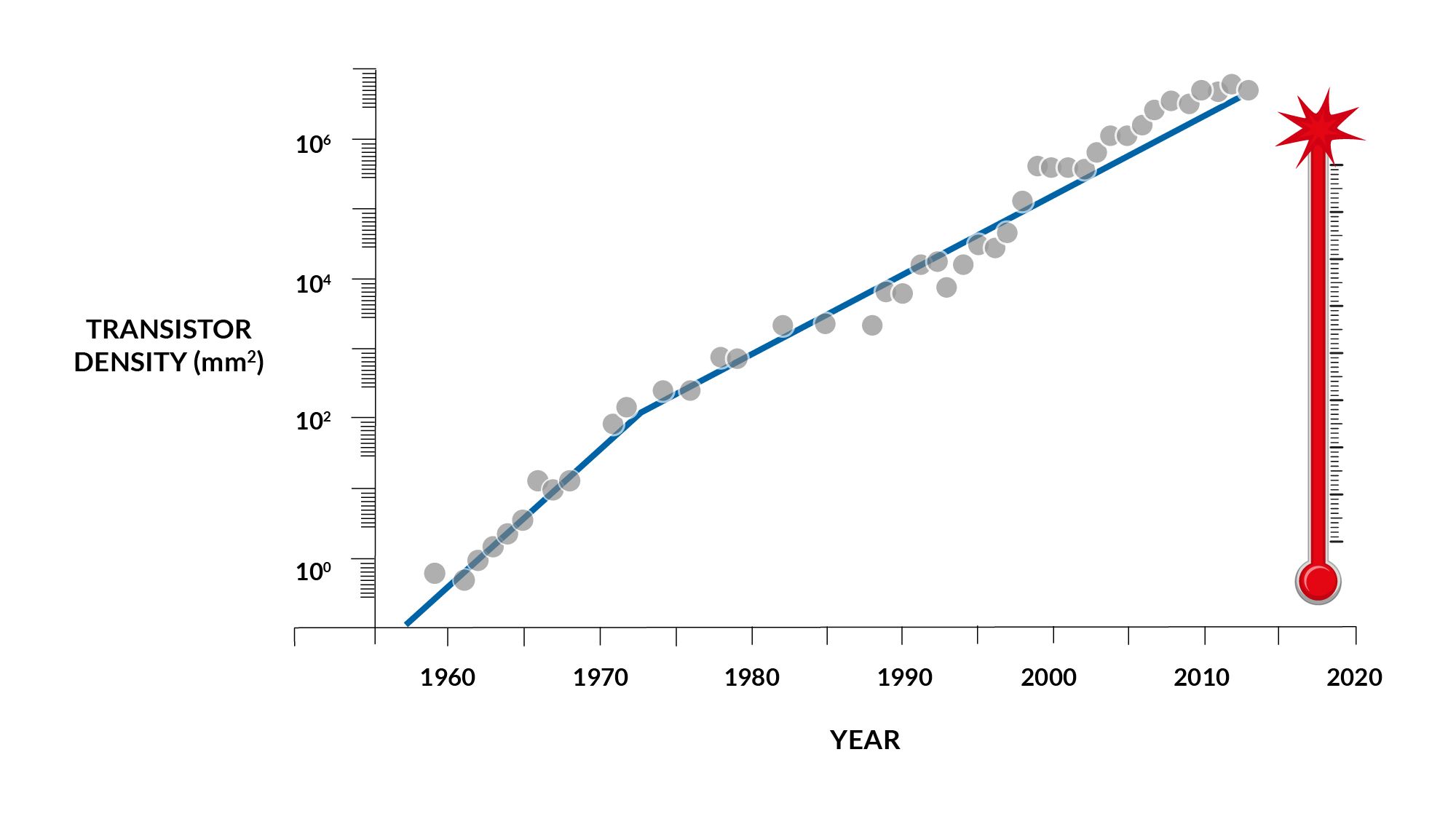

Things are heating up in the world of microprocessors — literally.

Next-gen CPUs will soon be packing more heat-emitting transistors into a single chip and increasing clock speed, creating cooling challenges and the condition known as "fatal-heat" — a predicament that both reduces the performance and compromises the lifespan of every component in a system.

So, what are the options for mitigating the high operating temperature resulting from power-hungry computers continuously processing and storing vast amounts of data in cryptocurrency mining operations and data centers?

This paper explores the benefits of liquid cooling for data centers and cryptocurrency mining operations, including its impact on efficiency, cost-effectiveness, and environmental sustainability.

Until recent years, the primary way of dissipating heat in a space full of powerful microprocessing technology was introducing cool airflow.

Using heat sinks and designing cooling systems to use the natural, upward flow of heat, combined with the use of fans to move air rapidly across the components has been the primary method of keeping CPU temperatures within optimal operating ranges since the mid-20th Century.

However, air has its limitations. It can only be as cool as the ambient, or surrounding, air.

Liquid Cooling Technology Finally Arrives in Data Centers

A technique that involves cooling computer components with a non-conductive fluid to dissipate heat, liquid cooling is a technology that was first used in 1887 for insulating and cooling high voltage transformers. It first appeared as a means of cooling computer equipment in the 1960s — and it took until the 21st Century for liquid cooling to appear in data centers.

Efficiency

One of the main benefits of liquid cooling for data centers and cryptocurrency mining operations is its impact on efficiency — it’s simply a more efficient method of cooling compared to traditional air-cooling systems.

During air cooling, heat is transferred from the computer components to the surrounding air, which is then cooled by a fan or air conditioning system. This process is not an effective medium for heat transfer, and air can only absorb a limited amount of heat.

In contrast, immersion liquid cooling, for example, involves cooling the computer components using a non-conductive fluid — or even water, such as JetCool’s JetPlates technology which has a higher heat capacity than air. This means that the fluid can absorb more heat, resulting in a more efficient cooling process.

Cost-Effectiveness

Liquid cooling can also be more cost-effective compared to traditional air-cooling systems because these systems require significant infrastructure, such as fans, ducts, and air conditioning units, which can be expensive to install and maintain.

Liquid cooling, on the other hand, involves utilization of a non-conductive dielectric fluid for cooling computer components, which can require less infrastructure.

Another advantage is reduced energy consumption and operating costs. Air cooling systems require a significant amount of energy, whereas immersion cooling requires less energy both because the fluid used for cooling can absorb more heat, and the cooling is taking place at the source of the heat.

Environmental Sustainability

Liquid cooling can also be more environmentally sustainable compared to traditional air-cooling systems that can create a significant carbon footprint due to the large amount of energy they consume. Liquid cooling, however, requires less energy, resulting in a lower carbon footprint.

Liquid cooling also reduces water consumption compared to traditional air-cooling systems that require a significant amount of water to cool the air conditioning units, which can result in significant water usage. Liquid cooling does not require water, and the fluid used for cooling can be reused.

Types of Liquid Cooling

There are two main types of liquid cooling: immersion and direct liquid cooling.

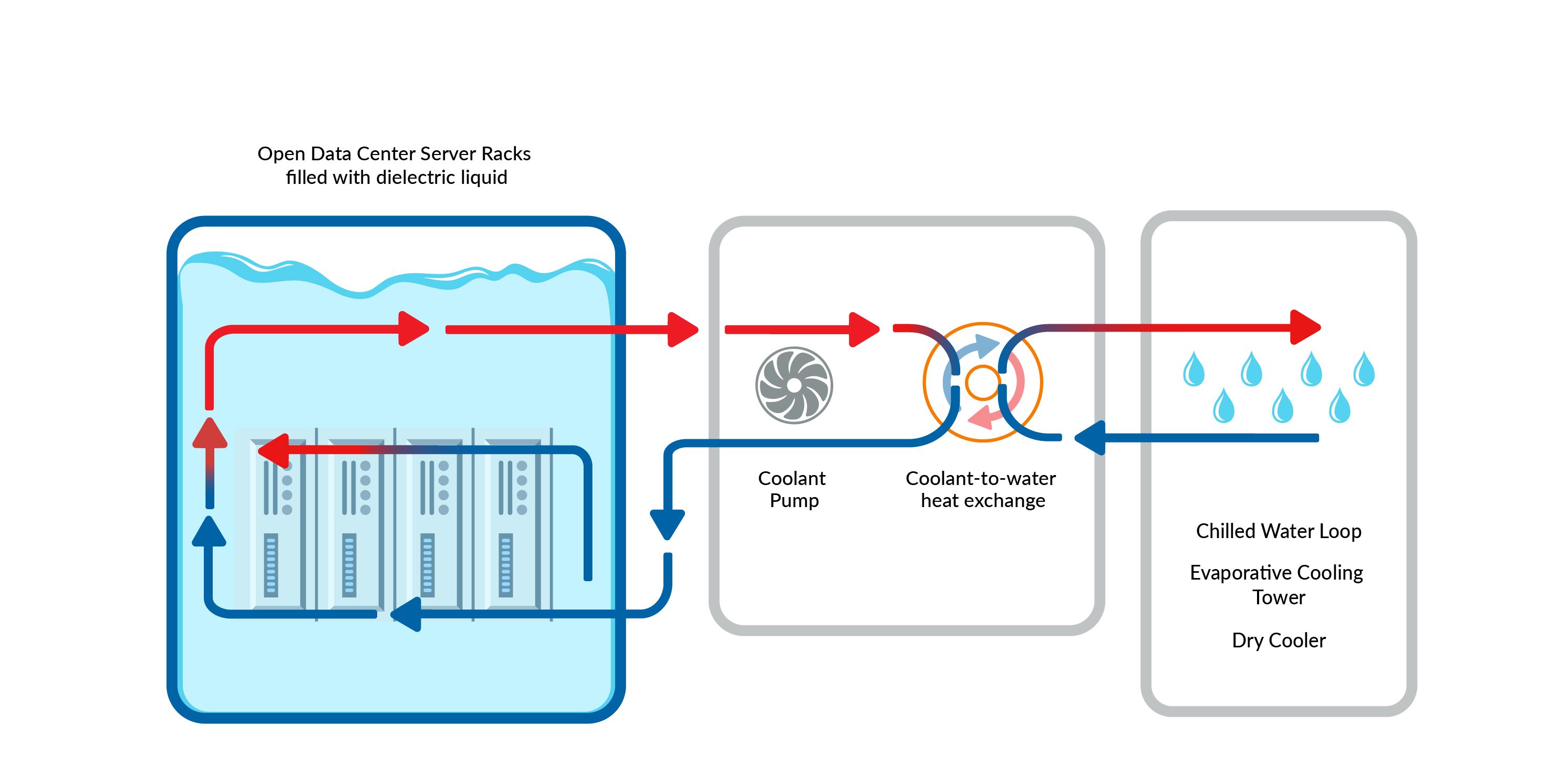

1. Immersion Cooling:

This is the process of placing a server or ASIC crypto miner, after removing the cooling fans, in a non-conductive liquid — typically a specialized mineral oil — then cycling that liquid over and through the equipment through a heat exchanger. This also allows the use of standard computing hardware.

There are two types of immersion cooling: single and two-phase.

- Single Phase Liquid Immersion Cooling: In single phase cooling, the dielectric fluid does not change state and the liquid remains a liquid throughout the cooling process. This is the simplest of the liquid cooling techniques and easiest to implement with existing hardware.

- Two-Phase (Phase Change) Liquid Immersion Cooling: In two-phase cooling, the dialectic fluid changes state, from liquid to vapor. It uses fluids with high thermal conductivity to absorb the heat generated by the component and evaporates it into a gas. The liquid is fluorocarbon with a boiling point of 50° C. Piping (flexible tubes) bring the dielectric fluid to a cold plate mounted directly on the chip. The heat is absorbed, causing the fluid to boil and convert into a gas which is then condensed back into a liquid state in a separate unit. That’s where the heat is dissipated. This type of cooling is more expensive and complex than other liquid cooling methods.

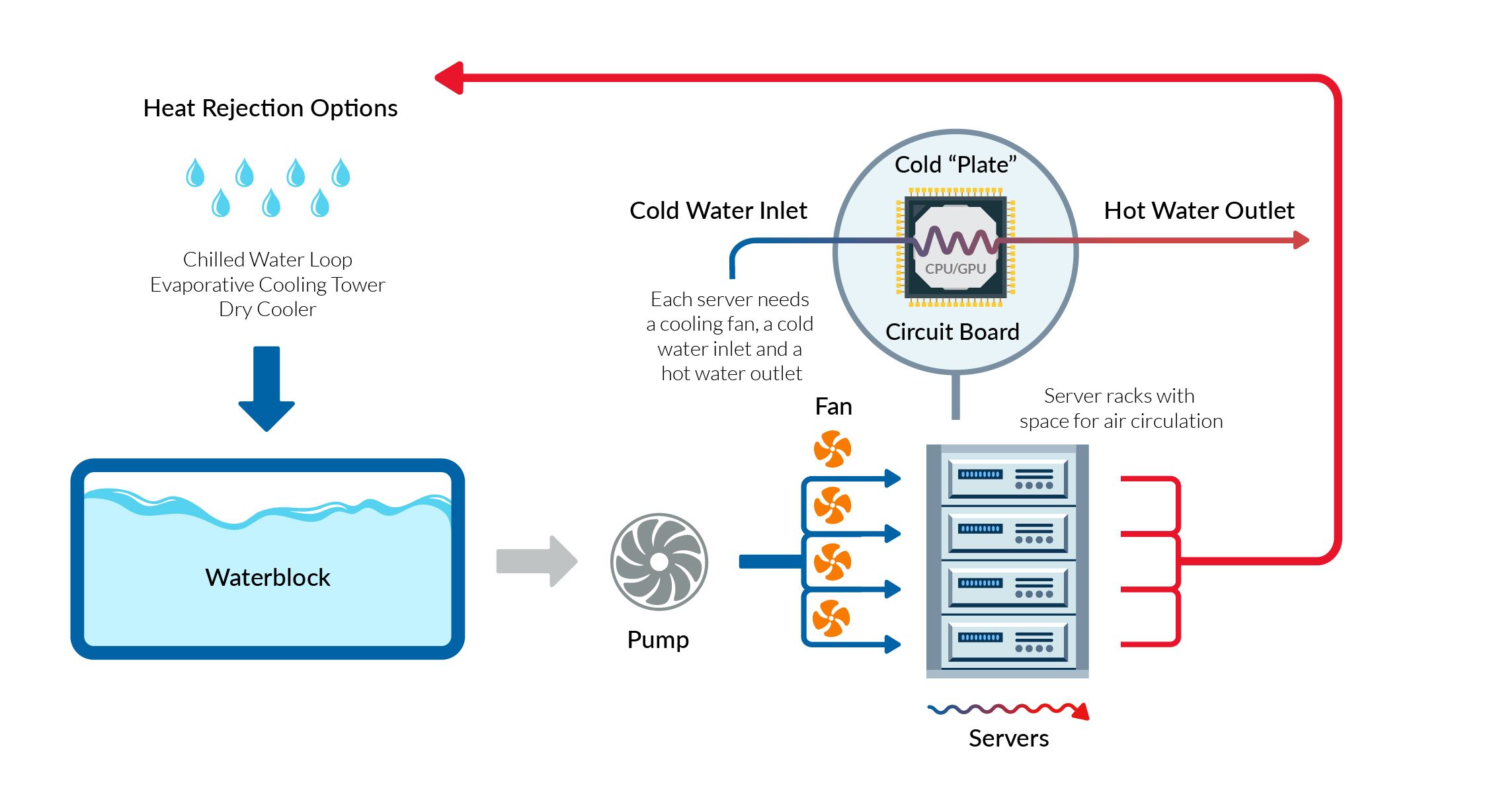

2. Direct Liquid Cooling / Direct to Chip Cooling:

Direct liquid cooling (DLC), or direct to chip cooling (D2CC) is a method that directly circulates liquid coolant over the surface of the chip.

In this process, the liquid coolant is typically pumped through a microchannel heat sink (cold plate) that is in contact with the chip. The heat generated by the chip is transferred to the coolant through the heat sink, and the coolant is then circulated to a radiator where the heat is dissipated into the surrounding environment.

Direct to chip cooling can provide better thermal performance compared to air cooling, as liquid has a higher heat capacity and thermal conductivity than air. This allows for more efficient heat transfer from the chip to the coolant. Additionally, direct to chip cooling can allow for higher overclocking and improved system stability because the cooler operating temperatures can reduce the risk of thermal throttling or system crashes.

How to Decide

With any technology, there are advantages and disadvantages to consider. In the sections below we will cover the general benefits and challenges of liquid cooling, then articulate the benefits and challenges of each specific type of liquid cooling we have covered.

Bottom Line Benefits of Liquid Cooling

- Improved cooling efficiency: Liquid cooling provides a higher cooling capacity compared to traditional air-based cooling systems. As the cooling fluid comes into direct contact with the heat-generating components, it can remove heat more efficiently.

- Reduced noise: Liquid cooling systems can significantly reduce the noise level in data centers. As there is no need for fans to move the air, the cooling process is much quieter.

- Increased equipment density: With liquid cooling, the data center can support higher equipment densities as the cooling system can accommodate more heat-generating equipment in the same physical space.

- Longer equipment lifespan: As the heat-generating components are kept at lower temperatures, liquid cooling can extend the lifespan of the equipment, reducing the frequency of equipment replacement and improving the return on investment.

- Energy efficiency: Liquid cooling can reduce the energy consumption of the data center by eliminating the need for fans, which consume a significant amount of power in traditional air-based cooling systems.

- Improved system reliability: Liquid cooling reduces the risk of equipment failure due to overheating, thereby improving the overall reliability of the data center.

- Reduced carbon footprint: Liquid cooling can reduce the carbon footprint of the data center by reducing energy consumption, resulting in lower greenhouse gas emissions.

Challenges of Liquid Cooling to Consider

- Maintenance and cleaning: Cooling fluids used in direct to chip cooling can accumulate debris, dust, and other contaminants, which can reduce the cooling efficiency and damage the electronics. Cleaning and maintaining the cooling system can be challenging and time-consuming.

- Cost: Direct to chip cooling systems can be expensive, especially when dealing with high-performance electronics. The cost of the cooling fluid, pumps, and other components can add up quickly.

- Leakage risk: Direct to chip cooling systems are more susceptible to leaks than traditional cooling methods. A leak in the cooling system can damage the electronics and cause downtime, which can be costly and disruptive.

- Environmental impact: The use of cooling fluids in direct to chip cooling can have an environmental impact. Some cooling fluids are hazardous and can pose a risk to human health and the environment if not handled and disposed of properly.

- Equipment damage or failure: Use of water in direct liquid cooling carries the risk of leakage directly onto circuit boards or into the computer chassis. Water + Electricity = Bad Outcome.

Bottom Line Benefits of Immersion Cooling

In addition to the aforementioned benefits of liquid cooling, immersion cooling can allow the use of standard computer hardware. With immersion cooling, it is possible to take off-the-shelf hardware, remove the fans and immerse it in the tank of non-dielectric fluid.

Challenges of Immersion Cooling to Consider

While immersion cooling has several benefits for data centers and cryptocurrency mining, it also presents some challenges, including the cost of implementation. Immersion cooling requires specialized equipment, such as tanks, pumps, and fluid, which can be expensive to install and maintain.

Additional challenges include:

- Compatibility with electronics: Immersion cooling fluids must be carefully selected to ensure that they do not damage the electronics. For example, some fluids may corrode the metal components or dissolve the insulating material.

- Space requirements: Immersion cooling systems require more space than traditional cooling methods. The equipment must be submerged in the cooling liquid, which can take up more floor space and make it difficult to access the components.

- Limited Compatibility: Immersion cooling may not be compatible with all types of computer components, as some components may not be able to withstand immersion in the coolant.

Bottom Line Benefits of Direct Liquid Cooling

- Scalability: DLC systems are highly scalable, making them ideal for data centers that need to add or remove equipment frequently.

- Modular design: DLC systems have a modular design, which allows for easier maintenance and upgrades.

- Flexibility: DLC systems can be configured in different ways to suit the specific needs of the data center, such as using different cooling liquids or incorporating different types of pumps.

Challenges of Direct Liquid Cooling to Consider

While direct to chip cooling provides advantages over other cooling methods, it also poses several challenges that include:

- Design complexity: Direct-to-chip cooling requires a specialized design that takes the cooling fluid directly to chip surface. This design can be complex and difficult to implement when dealing with high-density electronic components.

- Higher Cost: Direct liquid cooling systems can be more expensive than air or immersion cooling systems, as they require more hardware and can be more complex to install.

- Compatibility with electronics: Cooling fluids used in direct-to-chip cooling must be carefully selected to ensure that they do not damage the electronics. For example, some fluids may corrode the metal components or dissolve the insulating material.

Summary

You can prevent “fatal heat” from murdering your datacenter hardware.

Liquid cooling options for datacenter and cryptocurrency mining equipment are the most efficient way of controlling operating temperatures. This technology extends the life of components, allows for higher performance by overclocking and increases environmental sustainability.

Controlling the temperature enables taking control of your profitability.

This is where c3controls can help. With a wide selection of electrical controls and circuit protection components, c3controls can deliver the electrical products essential for keeping Everything Under Control.

Author's Note:

by Ted Wodoslawsky

One of the first things I learned about digital technology was the amount of heat it created. I started my career in the controls industry as a PLC Test Technician, testing and troubleshooting the individual circuit boards that made up the 1774-PLC system. One of those boards was the 1774-TB programming terminal interface module. It was made up of two circuit boards in a double-deck configuration. This was necessary to the storage limitations of EPROM technology at that time. All of those chips got hot — so hot, the EPROMs would work their way out of their sockets and could easily burn your fingers when you pulled the module out of its test chassis.

Controlling heat was a problem then, and it hasn’t stopped being a problem during the intervening 40+ years. It has only grown… hotter.

----------------------------------------

Descargo de responsabilidad:

El contenido proporcionado en este documento técnico está destinado únicamente a fines de brindar información general y se proporciona en el entendimiento de que los autores y editores no se dedican a la prestación de servicios de ingeniería, consultoría u otros servicios profesionales. La práctica de la ingeniería está impulsada por circunstancias específicas y únicas para cada proyecto. En consecuencia, cualquier uso de esta información debe realizarse solo con previa consulta a un profesional calificado y con licencia que pueda tener en cuenta todos los factores relevantes y los resultados deseados. La información de este documento técnico se publicó con un cuidado y una atención razonables. Sin embargo, es posible que parte de la información contenida en estos documentos técnicos esté incompleta, sea incorrecta o no se aplique a circunstancias o condiciones particulares. No aceptamos responsabilidad por pérdidas directas o indirectas que resulten de usar, confiar o actuar sobre la información en este documento técnico.

ISO 9001:2015

Certificado

Más de 17 millones de productos

Configuraciones

Toda la vida

Garantía

Garantizado

Envíos en el mismo día

Precios ventajosos

Ahorre hasta un 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009