What Is Pump Control?

Pump control is defined just as the name implies, control of any type of electrical pump or fan. This sounds simple enough. However, there are other considerations such as the strength of the power grid, utility or governmental regulatory requirements for solid state starters, discharge control, use of check valves, etc. All of this information leads us to several control methods for pumps including variable speed drive, soft starter, or direct-on-line starters (two speed, wye-delta, or single speed). None of these methods is right or wrong, they all need to be considered when selecting pump control.

Considerations when selecting pump control

Because each application is unique this paper addresses the following basic considerations when selecting pump control.

- Utility or governmental regulations typically determined by motor size and the strength of the power grid.

- Size of the motor.

- Discharge or output control (pressure, temperature, volume etc.).

- Closed or open pumping system (re-cycle cooling fluid, irrigation, “clean” water, wastewater etc.).

- Type of material being pumped (liquid, volatile, dry, gas etc.).

- Pump efficiencies.

- Type of throttling required (mechanical or speed).

- Check valve.

- Total Harmonic Distortion (THD) requirements.

Basic Pump Control

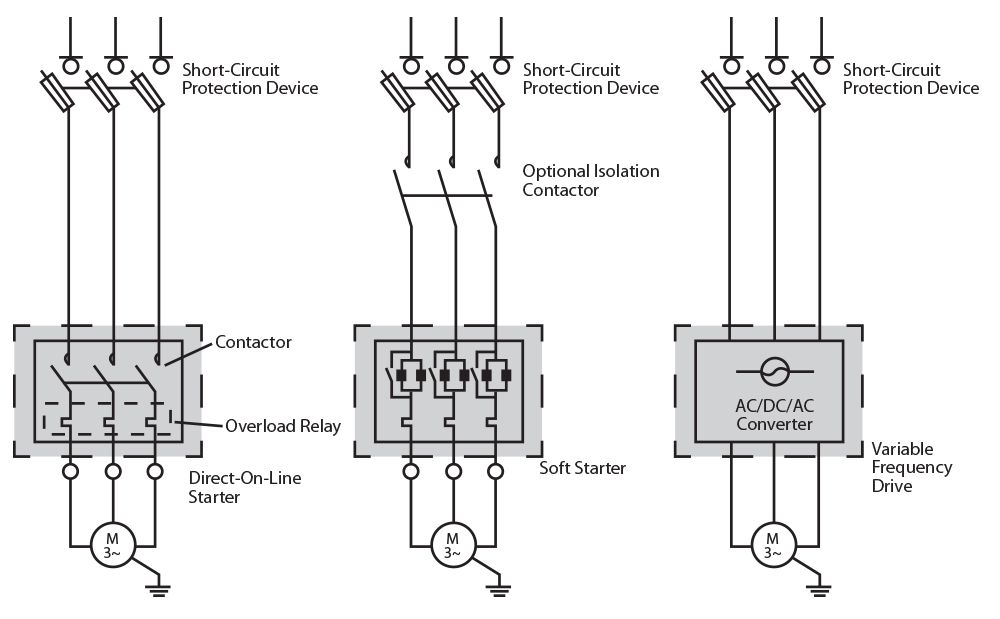

There are three basic control methods to apply to a motor-pump combination.

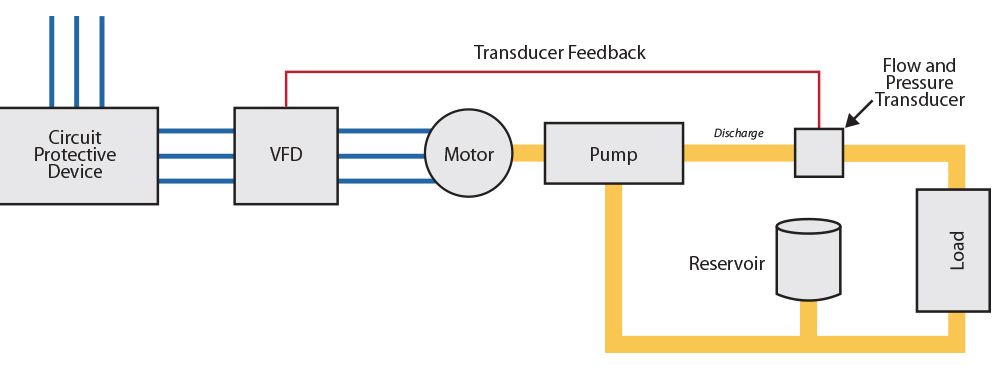

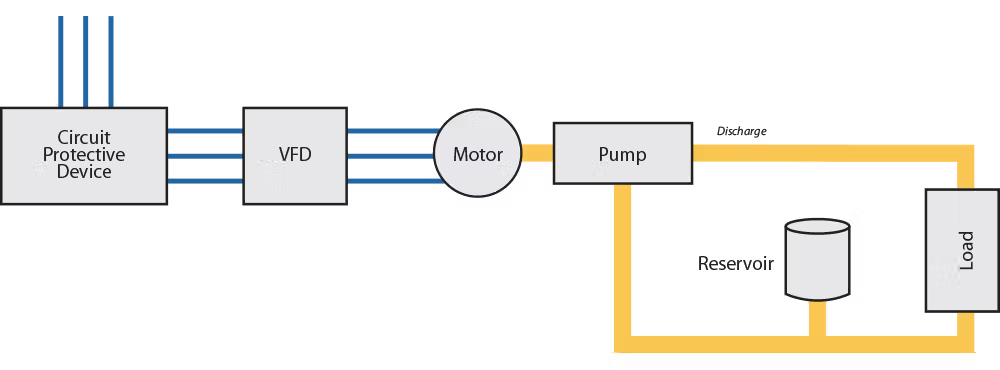

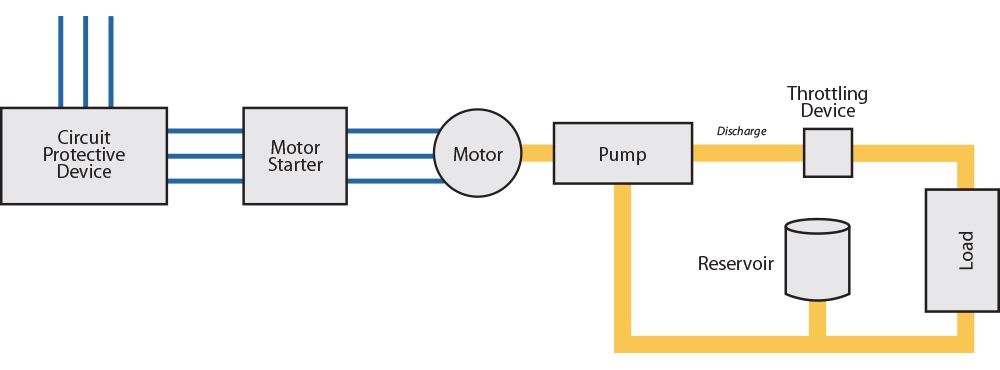

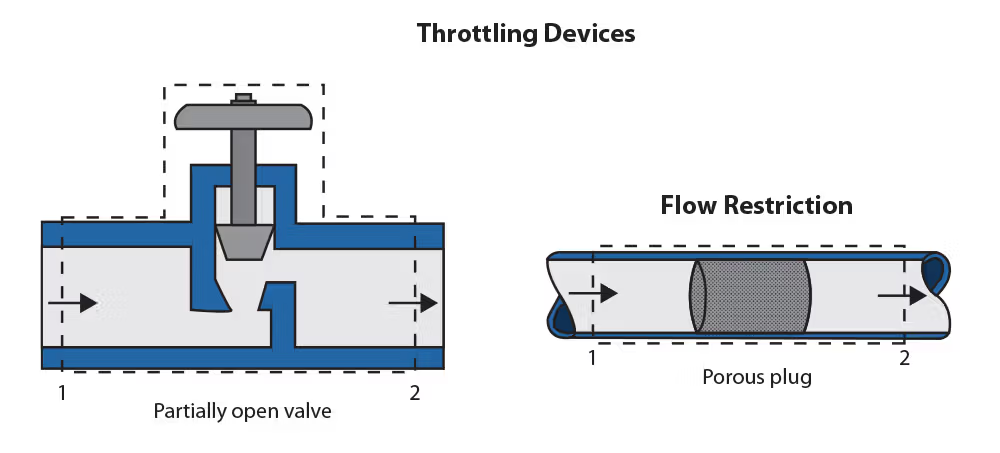

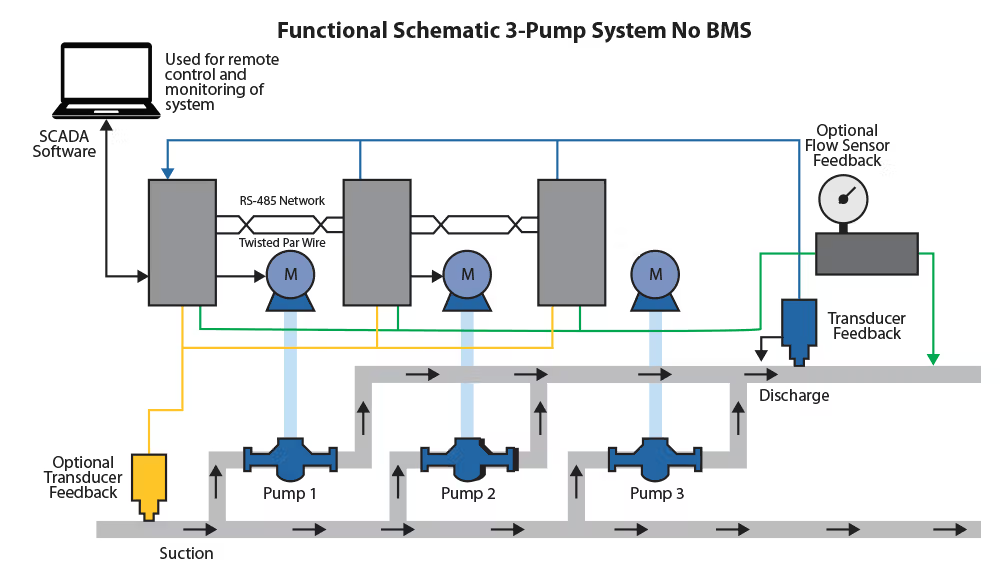

Pump Discharge Control

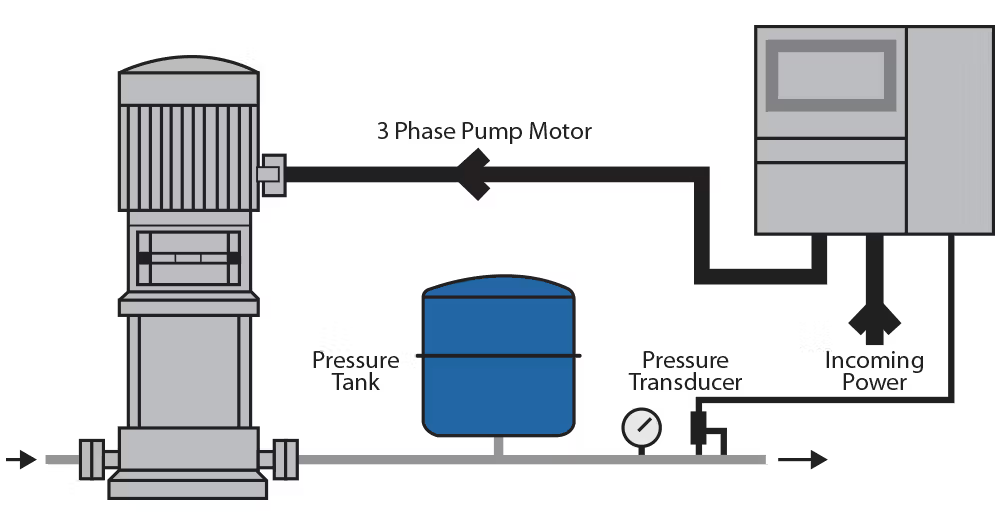

One of the top items to consider is the discharge rate and pressure (force). This can be accomplished by varying the output of the pump or mechanical “throttling”. The variable output is accomplished via pump speed control by using a variable speed drive. The speed is dependent on the feedback transducer or transducers (flow and pressure). A direct-on-line starter can be either an electro-mechanical starter or a soft starter. The discharge is controlled by mechanical or electro-mechanical throttling. Mechanical throttling can be done via a proportional valve, regulator, restrictor plate, electrical regulator or valve, etc. Keep in mind that some applications do not require any type of throttling. See the following diagrams.

Direct-On-Line (DOL) Starter

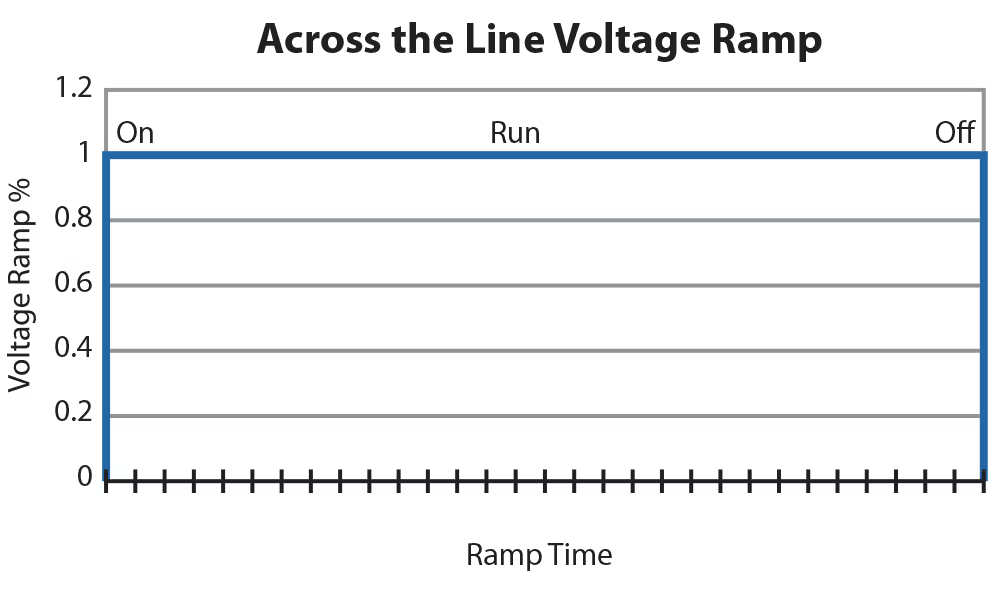

There are two types of direct-on-line starters; electromechanical (contactor) and solid state (soft starter). One can use either of these starting methods, but consideration needs to be given to the system, power grid, and government/utility regulations. With either of these starting types the discharge volume, pressure, water hammer, and mechanical coupling is a consideration.

Example:

- A pump system with a mechanical regulator will adjust to the preset requirements to meet the flow or pressure on the discharge.

- A pump system with a proportional valve, requires the adjustment of the valve to meet the flow or pressure on the discharge.

- A pump system with an orifice plate will have a predetermined flow rate.

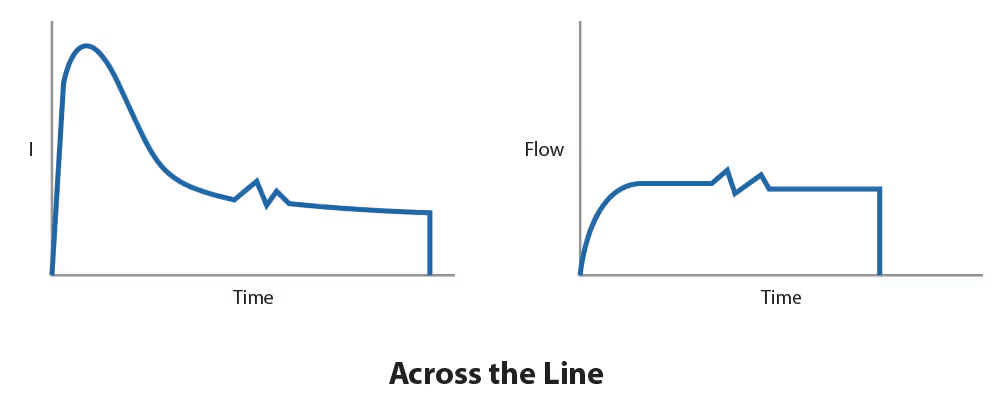

Contactor Starters

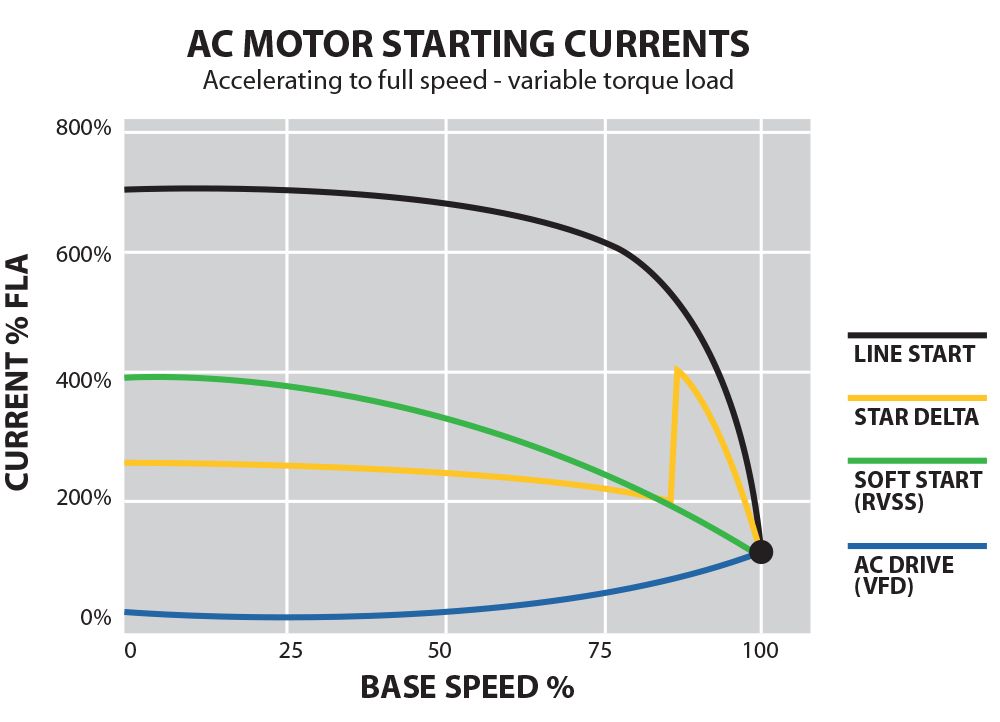

Mechanical starters are contactors combined with an overload relay. The overload relay provides thermal protection to the motor. Mechanical starters have evolved over the years. They have actually been used in industry for over 100 years. They are a very proven form of technology. Of the three starting types this is one of the least expensive to implement. However, when full line voltage is applied to a motor, significant inrush current and abrupt starting/stopping occurs. In today’s environment, mechanical starters are typically used with motors ≤10hp. A good application for mechanical direct-on-line starters is on systems that don’t require precision flow and/or pressure of the discharge.

Soft Starters

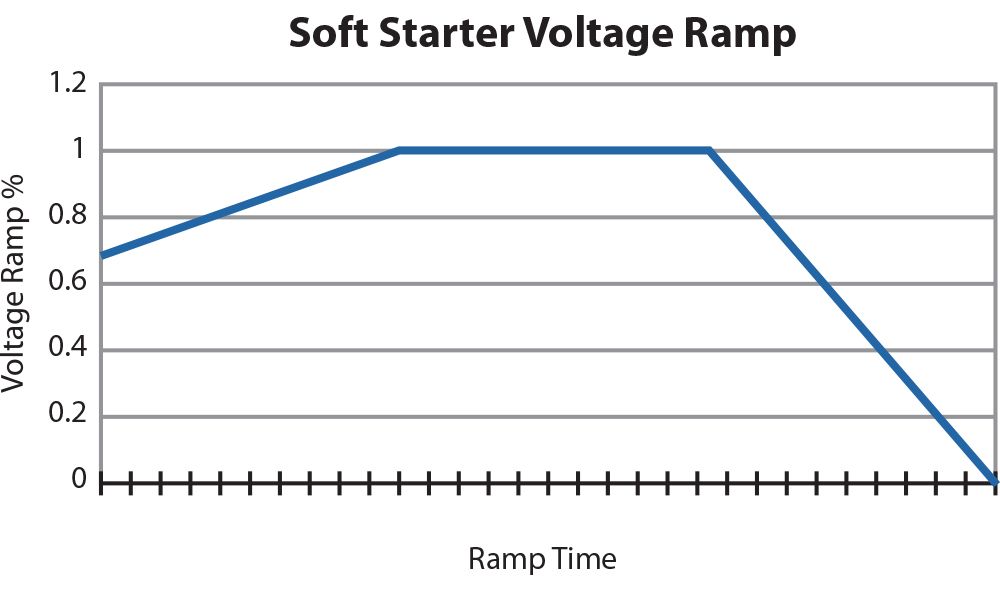

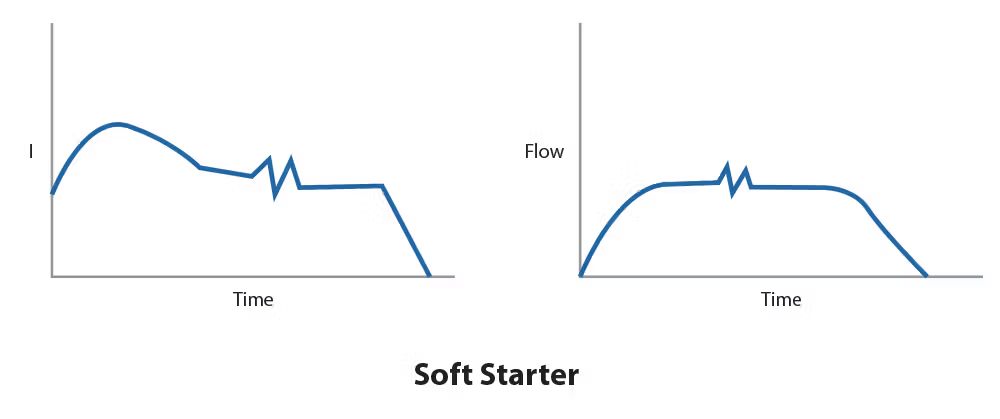

A soft starter is a solid state starter that works by reducing the voltage up or down to start/stop the motor, thus limiting the inrush current. Soft starters provide a solid state alternative to a mechanical starter, thus bridging between the mechanical starter and variable speed drive. To reduce the energy dissipated and prolong the life of the solid state circuit components a run or bypass contactor is pulled in during the run portion of the cycle. The typical soft starter circuit has start and stop, this could be a flow or pressure switch.

Applications: Based on feedback from the power utility industry, solid state starts (VFD/ASD or soft starters) are required on motors starting at sizes between 25hp and 75hp. The speed of the pump cannot be controlled or has a fixed discharge rate, meaning the discharge has to be controlled via mechanical or electro-mechanical systems.

Variable Frequency or Adjustable Speed Drive

Transducer feedback for the flow, volume, and/or pressure can be used as input to a variable frequency drive (VFD) or adjustable speed drive (ASD). This allows the VFD/ASD to vary the speed of the motor by comparing the transponder reading to the set point. The VFD/ASD pump can also be set to a pre-determined speed with no transducer feedback, this is often referred to as open loop. This open loop system is typically used for irrigation or transfer.

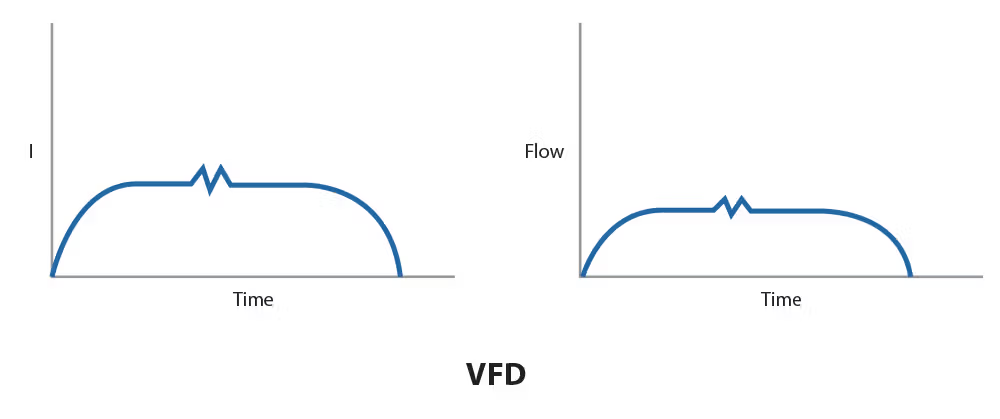

Starting Current and Flow of various starting methods

When considering which type of starting method to use, a point of consideration is the amount of current it takes to bring the motor to speed, and the flow. Generally speaking, the simpler (and less expensive) the method the more energy it will take to control the electric motor of the pump.

Selecting Pump Control Components

Selecting pump control components may require some assistance. We can help you make sure you have everything under control with your electrical system. c3controls offers the following pump-control products.

- Contactors

- Overload Relays

- Direct-On-Line (DOL) Starters

- Enclosed Starters

- Miniature Circuit Breakers

- Terminal Blocks

- Terminal Block Relays

- Pilot Devices

- Wire Duct

Contact c3controls for proper selection and sizing of control panel components.

--------------------

Disclaimer:

The content provided in this white paper is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information in this white paper was posted with reasonable care and attention. However, it is possible that some information in this white paper is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this white paper.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009