Introduction

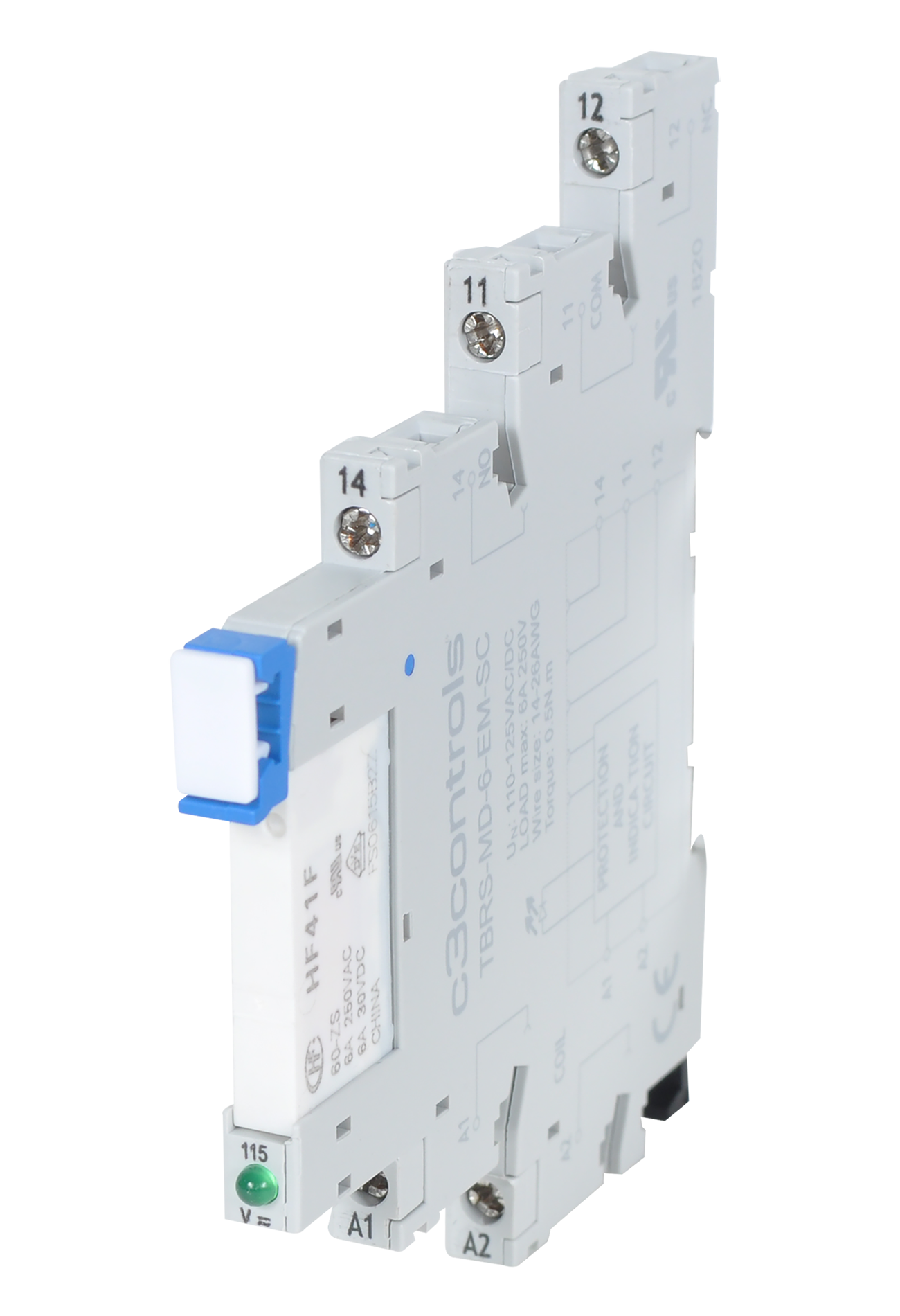

When you first look at this product, there are high chances that you would confuse it with a terminal block. It is sometimes called a Terminal Block relay. Many people also refer to them as an Interface relay or Interposing relay for its application in control panels for isolation. It is also called a Slimline relay, because of its ultra-slim width of just about 6mm. That’s four different names for the same device! We will discuss these and the applications in detail, later. For now, if you haven’t seen this relay before, here’s a first look for you.

If you have been working in control and automation for any length of time, you probably have a good idea why this relay is useful and its necessity. As automation grows and evolves, control panels have become smarter and smaller. Nearly all of them house a controller, incorporating these terminal block relays ensure reliable switching of process I/O while ensuring controller safety. Due to their size, simplicity of DIN rail mounting and the same level of performance as General purpose relays, they are now becoming the first choice of panel shop builders and OEMs.

Let’s take a look at the detailed construction of this product before we dive deep.

Essential Components of a Terminal Block Relay Assembly

There are 2 essential components of assembly that makes a Terminal Block Relay:

- Relay - This is the heart of this assembly. The relay is either of Electromechanical or Solid-state type which includes input (e.g. coil) and output (Contacts) components.

- Socket - This is a housing with a Terminal Block like profile which provides easy connection to the relay terminals (through screw or screwless terminals), arrangement for jumper connection for easy wiring between neighboring devices, and DIN rail mounting. Further, the same socket also includes a circuit, primarily which modifies an input signal to lower level (as per relay coil requirement). In some cases, the circuit also makes room for coil surge protection, leakage current suppression, LED indication etc. (We will talk about these features.)

Features That Should Be Considered

Now that you are familiar with Terminal Block Relays and their construction, let’s discuss the rest of the features of this Relay which should be considered.

- Even with its compact size, the actual relay is pluggable or replaceable which provides you a much-needed flexibility. In case of malfunction, there is no need to replace a complete Terminal Block Relay assembly.

- Super bright and visible LED indication at the front of this assembly to inform you about a contact state at a glance.

- The coil of an Electromechanical version of relay generates a spike of voltage at the time of switching off , which can potentially damage nearby circuitry. A Terminal Block relay with built-in protection against Coil surge is highly preferred.

- It is absolutely necessary that the relay should switch its contact state only when it is intended. The relay should not turn itself ON due to leakage current of a PLC (Programmable Logic Controller). A few of the Terminal Block Relays that are available in the market do provide the provision of leakage current suppression to avoid nuisance coil turn-on.

- Another common feature that can be seen on the majority of Terminal Block Relays is a provision for marking. This helps you to identify or differentiate between various circuits in the panel.

Choosing A Variant for Your Application

Let’s look at the variants available under this product category and how you would choose one that suits your application perfectly. So, same as other relays, Terminal Block Relay manufacturers often provide you with an option of either electromechanical (EM) or Solid-state relay (SSR) construction. Although SSRs have some advantages over EM relays in terms of switching speed, the robustness of EM relays delivers a long life, making EM relays lead the race, at least in control panel installations. Electromechanical relays provide multiple contact options like Single Pole Double Throw (SPDT) & Double Pole Double Throw (DPDT). Whereas, SSRs are generally seen with 1 Normally Open contact.

Based on the above specifications, after considering load/ application requirements and availability of input voltage, the desired Terminal Block Relay can be selected.

Most manufacturers provide a choice in terms of termination i.e. screw type or push-in (spring clamp) terminals, and some may also provide a different version for Class 1, Div. 2 Hazardous Location.

When switching a very low power load, you should consider Terminal Block Relays that utilize Gold plated contacts, as they have very low contact resistance.

Applications and Practical Use Cases

Finally, let’s look at some applications and practical use cases of Terminal Block Relays

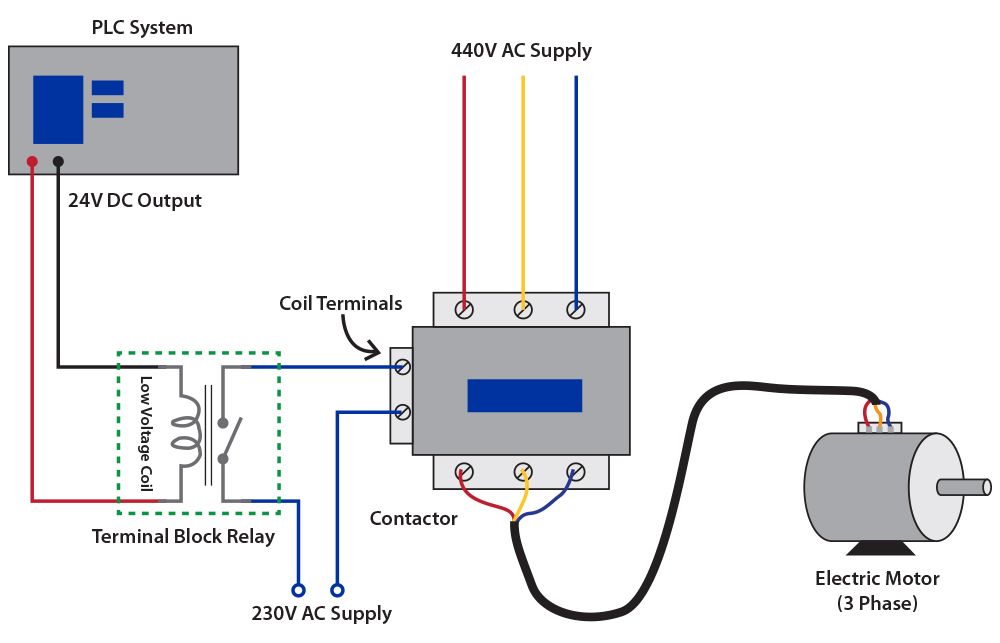

There are broadly two major applications, and they may overlap in some cases. Terminal Block Relays are used between a controller (e.g. PLC) and a high-power load (a motor), mainly for 2 reasons:

- When a controller is not able to drive the load directly (due to different voltage requirements and insufficient driving current)

- For electrical isolation

Here’s an example to simplify the above:

Here, our application is to remotely operate a 440V 3-phase motor through a contactor. The contactor requires a 230V AC supply across its coil. Now, because the PLC can only provide 24V DC signal against the requirement of 230V, a Terminal block relay is used as an interposing relay. It is energized using PLC output, the contacts of the relay then switch the contactor coil to drive the motor. In this case, we are not only operating a motor through PLC but also isolating the low voltage controller and control circuit from higher voltage power circuit.

Accessories

To get the most out of Terminal Block Relays, use them with accessories. Here is a list of highly useful accessories that you should be looking for when buying Terminal Block Relays:

- Replacement Relay - As the actual relay of TBR is pluggable, make sure the manufacturer is providing replacement relays. This is a cost savings, because you would not be required to completely replace the assembly in case of malfunction.

- Jumper - When you need to loop the same wire across many relays, this accessory is very useful as it provides a secure connection while eliminating intensive labor work. This can also be cut to match the number of devices you want to connect.

- Spacer - To differentiate between various circuits/devices in the control panel, the use of a spacer, also called a separator plate, perfectly serves this purpose.

- Replacement Marker - Most of the manufacturers provide markers with TB relays, but there are chances of those getting misplaced, so it is helpful to have replacements on-hand.

These accessories also provide a very clean and organized look to your control panel.

c3controls TBR Offering

Good news! c3controls is currently offering 6A SPDT Terminal Block Relays with all the essential features and aforementioned accessories as well. Check them out here!

Disclaimer: The content provided in this white paper is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information in this white paper was posted with reasonable care and attention. However, it is possible that some information in this white paper is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this white paper.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009